Features:

1. It integrates three functions: dehumidification, drying, and two-stage feeding.

2. It is widely used in engineering plastic materials with strong moisture absorption, such as: PA.PC.PBT.PET, etc.

3. Equipped with a honeycomb runner to obtain a stable and low-dew dry air. The shape is divided into two types: semi-open and fully enclosed.

4. The feeding system is equipped with a shut-off valve to ensure that there is no residual material in the material pipe.

5. All models are equipped with a closed loop feeding system to prevent the dried raw materials from being damp again due to external air.

6. Three-stage feeding function can be selected. All models adopt double-layer moisturizing drying barrels with lower air blowing design to prevent heat energy loss and improve drying efficiency.

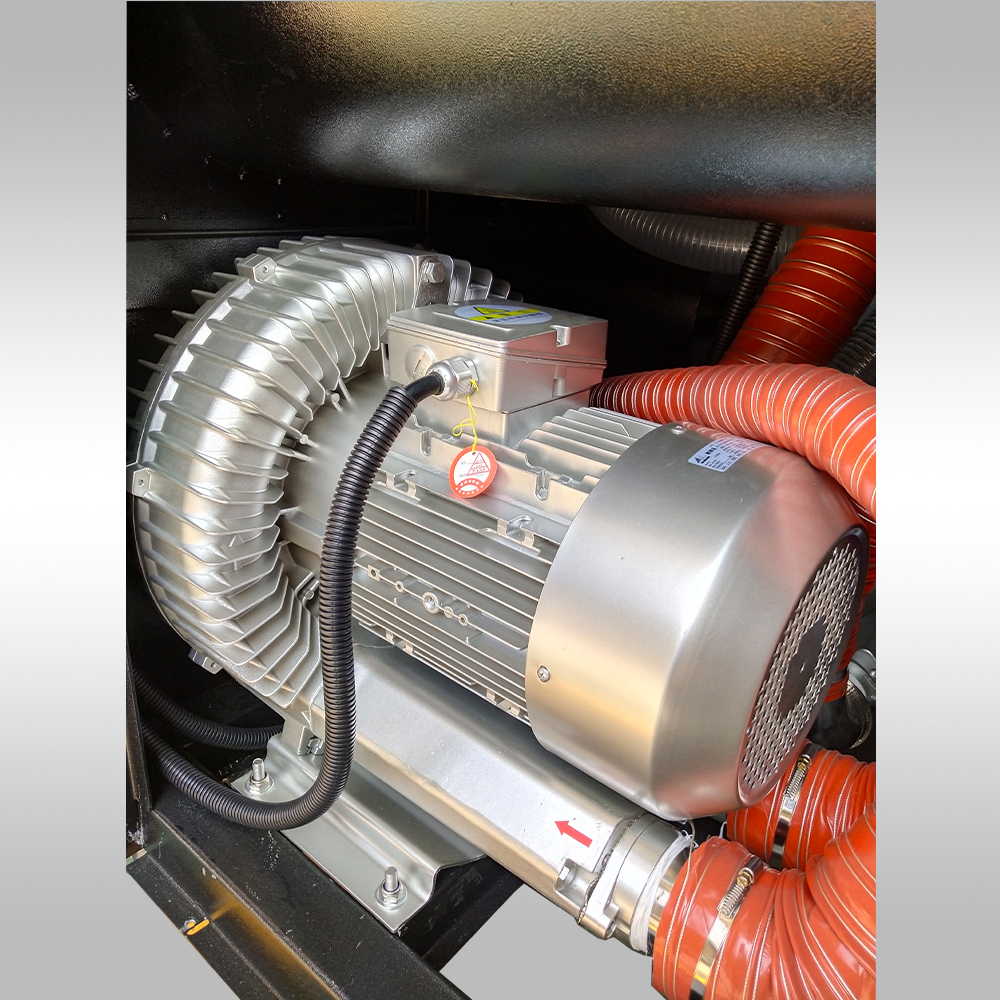

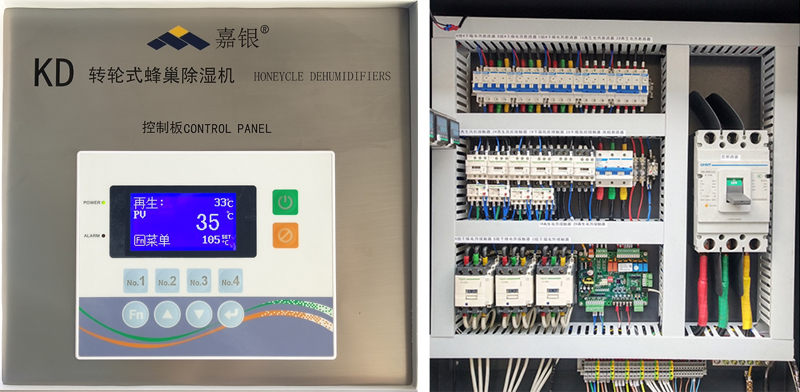

7. Equipped with safe and reliable Schneider electronic components and Guangzhou Bangpu LCD screen computer version, precise temperature control, one-key cutting in Chinese and English, easy operation, export standard.

8. Equipped with alarm indicator and fault display on the LCD screen, it is convenient to monitor faults at any time during work and deal with them in time, improving the efficiency of handling emergency situations.

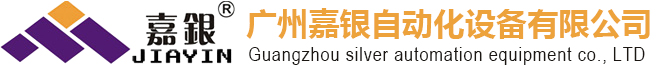

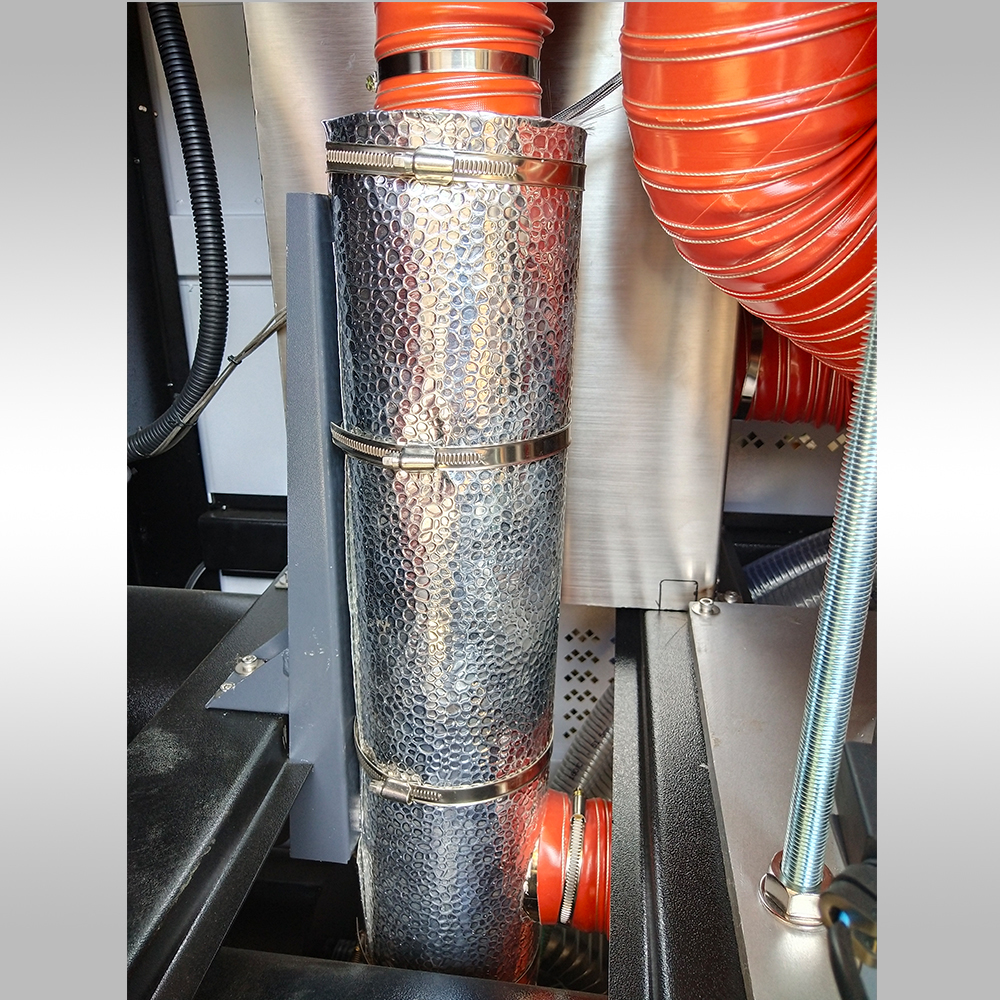

9. The Swedish honeycomb is matched with an imported motor and return air filter to ensure that the honeycomb is not polluted by raw material dust and is more durable.

10. Double condenser design to ensure lower return air temperature and dew point.

11. The heating barrel adopts the thickest double-layer insulation to avoid heat dissipation and high efficiency and energy saving.

12. Large machines are equipped with ladders and protective fences, which greatly improves the safety of maintenance and maintenance workers in daily production.

Electrical Control:

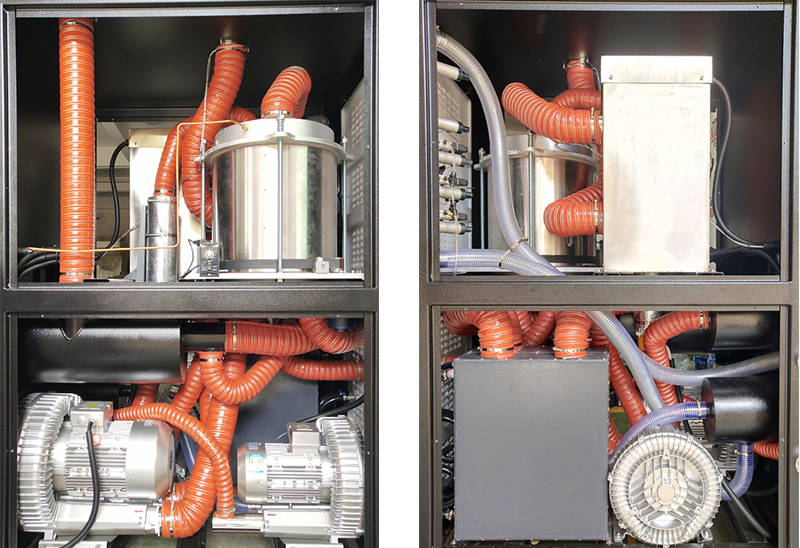

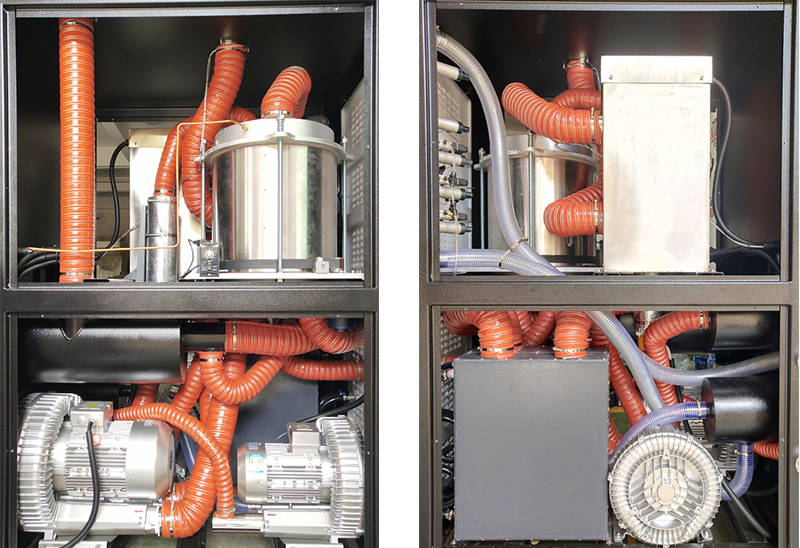

Internal Structure:

Standard:

Model MCD- | Drying system | Dehumidification system | Suction system |

Regenerative heating power(KW) | Drying fan power(KW) | Insulation tank capacity(L) | Regenerative heating power(KW) | Regenerative fan power(KW) | Dehumidification air volume(m3/hr) | Feed fan power(KW) | Suction machine piping

(inch) | Vacuum hopper(L) | Electric eye hopper(L) |

30H/20L | 3 | 0.2 | 20 | 3 | 0.2 | 30 | 0.75 | 1.5 | 3 | 3 |

30H/40L | 3 | 0.2 | 40 | 3 | 0.2 | 30 | 0.75 | 1.5 | 3 | 3 |

50H/40L | 4 | 0.55 | 40 | 3 | 0.2 | 50 | 1.1 | 1.5 | 6 | 6 |

50H/80L | 4 | 0.55 | 80 | 3 | 0.2 | 50 | 1.1 | 1.5 | 6 | 6 |

80H//120 | 6 | 0.75 | 120 | 3 | 0.2 | 80 | 1.5 | 1.5 | 7.5 | 7.5 |

80H/160L | 6 | 0.75 | 160 | 3 | 0.2 | 80 | 1.5 | 1.5 | 7.5 | 7.5 |

130H/160L | 6 | 1.1 | 160 | 3 | 0.2 | 130 | 1.5 | 1.5 | 7.5 | 7.5 |

130H/230L | 6 | 1.1 | 230 | 3 | 0.2 | 130 | 1.5 | 1.5 | 7.5 | 7.5 |

160H/230L | 7.2 | 1.5 | 230 | 4 | 0.55 | 160 | 1.5 | 1.5 | 12 | 12 |

160H/300L | 7.2 | 1.5 | 300 | 4 | 0.55 | 160 | 1.5 | 1.5 | 12 | 12 |

220H/300L | 7.2 | 2.2 | 300 | 4 | 0.55 | 220 | 1.5 | 1.5 | 12 | 12 |

220H/450L | 7.2 | 2.2 | 450 | 4 | 0.55 | 220 | 1.5 | 1.5 | 12 | 12 |

300H/450L | 15 | 3 | 450 | 7.2 | 0.75 | 300 | 1.5 | 1.5 | 12 | 12 |

300H/600L | 15 | 3 | 600 | 7.2 | 0.75 | 300 | 1.5 | 1.5 | 12 | 12 |

400H/600L | 18 | 3.8 | 600 | 7.2 | 0.75 | 400 | 1.5 | 1.5 | 12 | 12 |

400H/750L | 18 | 3.8 | 750 | 7.2 | 0.75 | 400 | 1.5 | 1.5 | 12 | 12 |

500H/750L | 21 | 5.5 | 750 | 10 | 1.5 | 500 | 1.5 | 1.5 | 12 | 12 |

500H/900L | 21 | 5.5 | 900 | 10 | 1.5 | 500 | 2.2 | 2 | 24 | 24 |

700H/900L | 24 | 7.5 | 900 | 10 | 1.5 | 700 | 2.2 | 2 | 24 | 24 |

700H/1200L | 24 | 7.5 | 1200 | 10 | 1.5 | 700 | 2.2 | 2 | 24 | 24 |

1000H/1500L | 32 | 9 | 1500 | 15 | 2.2 | 1500 | 2.2 | 2 | 24 | 24 |