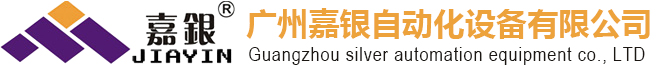

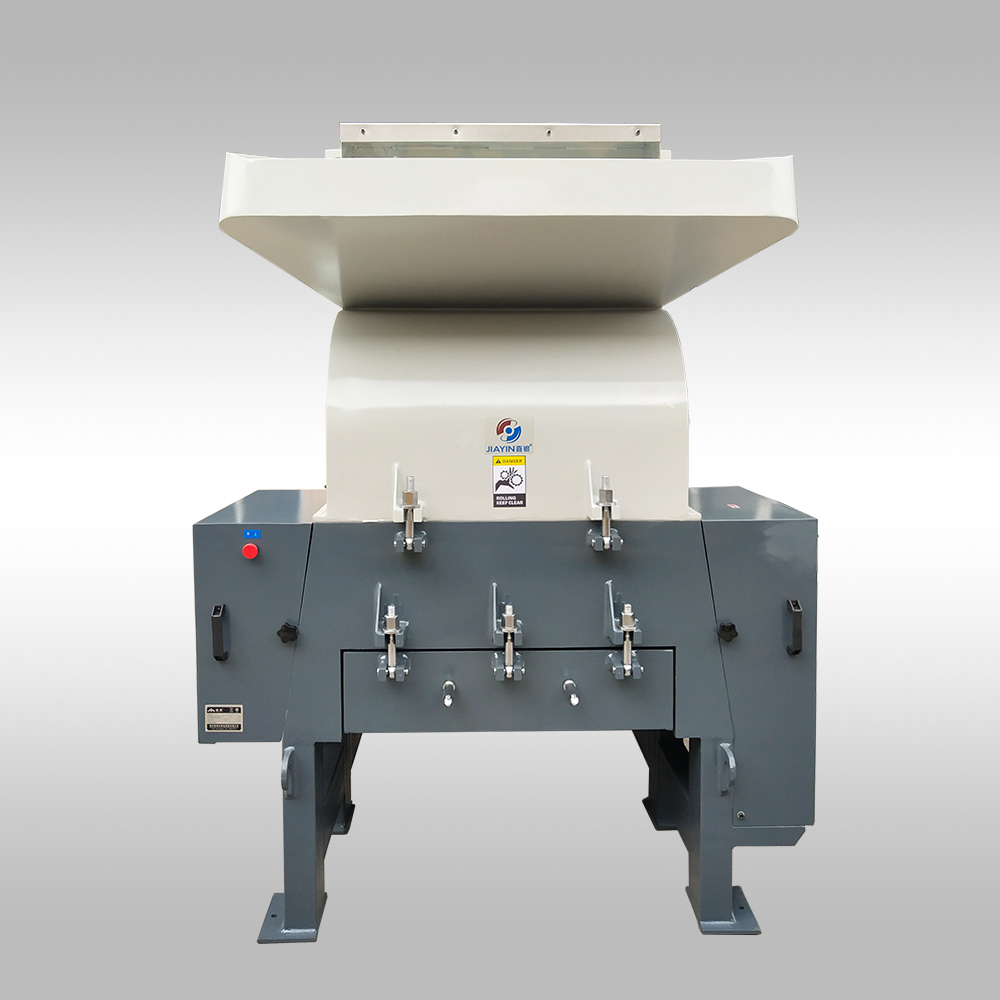

Features:

1. MSC series grinder, there are 6 knife types for customers to choose. It has a wide range of applications, and can be used to crush and recycle plastic products of various materials and shapes.

2. The design of the lower lock blade increases the cutting angle of the blade and improves the cutting efficiency. The shape of the formed particles is uniform and the powder is less. It can be divided into "D" flat knife type and "Y" claw knife type for wider application.

3. "I" type and "V" type knives are specially designed to crush PP, PE bottles, cans, barrels and waste paper, film, woven bags and other materials of different materials.

4. The feeding nozzle has double-layer sound insulation and low noise

5. Adopt high-quality bearings and large-mass inertia wheel design with strong crushing ability.

6. The blade is made of high chromium alloy steel with good toughness. Good wear resistance, adjustable blade extension length can be used repeatedly.

7. Equipped with electric control safety protection device to ensure safe operation. Compact structure, no hidden materials, easy to clean, easy to use and maintain

The unique rear fixed knife upper installation design, easy to replace, improve the efficiency of blade replacement.

Crushing knife type:

Standard:

Model | Smash caliber

(mm) | Power

(KW) | Rotary knife type

Number of knives (PCS) | Number of fixed knives

(PCS) | Crushing ability

(kg) | Dimensions

(cm) | Weight

(kg) |

“V”

type | “I”

type | “D”

type | “Z”

type | “P”

type | “Y”

type |

MSC-0305 | 265*220 | 4 | / | 3 | / | / | 15 | / | 2 | 100-200 | 65*95*110 | 240 |

MSC-0575 | 320*220 | 5.5 | / | / | / | / | 9 | / | 2 | 120-240 | 70*100*125 | 300 |

MSC-7510 | 380*240 | 7.5 | / | 3 | / | 6 | 12 | / | 2 | 150-300 | 83*110*133 | 500 |

MSC-7515 | 500*280 | 11 | / | 3 | / | 6 | 15 | / | 2 | 200-400 | 93*128*140 | 600 |

MSC-1520 | 520*320 | 15 | 6 | 3 | / | 6 | 15 | / | 2 | 300-500 | 108*150*170 | 1000 |

MSC-2030 | 630*360 | 22 | 6 | 3 | / | 6 | 21 | / | 2 | 500-800 | 120*168*181 | 1250 |

MSC-0350 | 710*500 | 37 | 6 | 3 | / | 6 | 21 | / | 2 | 600-1200 | 145*215*208 | 2000 |

MSC-5075 | 800*630 | 45 | 6 | / | / | 6 | 21 | / | 4 | 800-1500 | 160*210*262 | 2500 |

MSC-75100 | 1020*800 | 55 | / | / | 9 | / | / | / | 4 | 900-1800 | 188*242*268 | 3800 |

MSC-75120 | 1220*820 | 55 | / | / | 12 | / | / | / | 4 | 1000-2000 | 220*252*322 | 4500 |

MSC-75150 | 1520*1000 | 75 | / | / | 15 | / | / | / | 6 | 1100-2200 | 242*262*360 | 6000 |

MSC-600P | 600*360 | 15 | / | / | / | / | 18 | / | 4 | 300-500 | 120*150*180 | 900 |

MSC-600C | 620*380 | 22 | / | / | / | / | 18 | 18 | 2 | 500-800 | 125*162*188 | 1100 |

MSC-700P | 710*460 | 22 | / | / | / | / | 21 | 21 | 2 | 600-800 | 141*195*200 | 1400 |

MSC-800P | 810*460 | 30 | / | / | / | / | 24 | 24 | 4 | 600-1000 | 151*205*208 | 1700 |

MSC-800C | 810*510 | 37 | / | / | / | / | 24 | / | 4 | 600-1200 | 153*212*226 | 2000 |

MSC-900P | 910*510 | 37 | / | / | / | / | 27 | 27 | 4 | 700-1200 | 163*216*227 | 2300 |

MSC-1000P | 1020*650 | 45 | / | / | / | / | 30 | 30 | 4 | 800-1500 | 182*235*240 | 2800 |