Features:

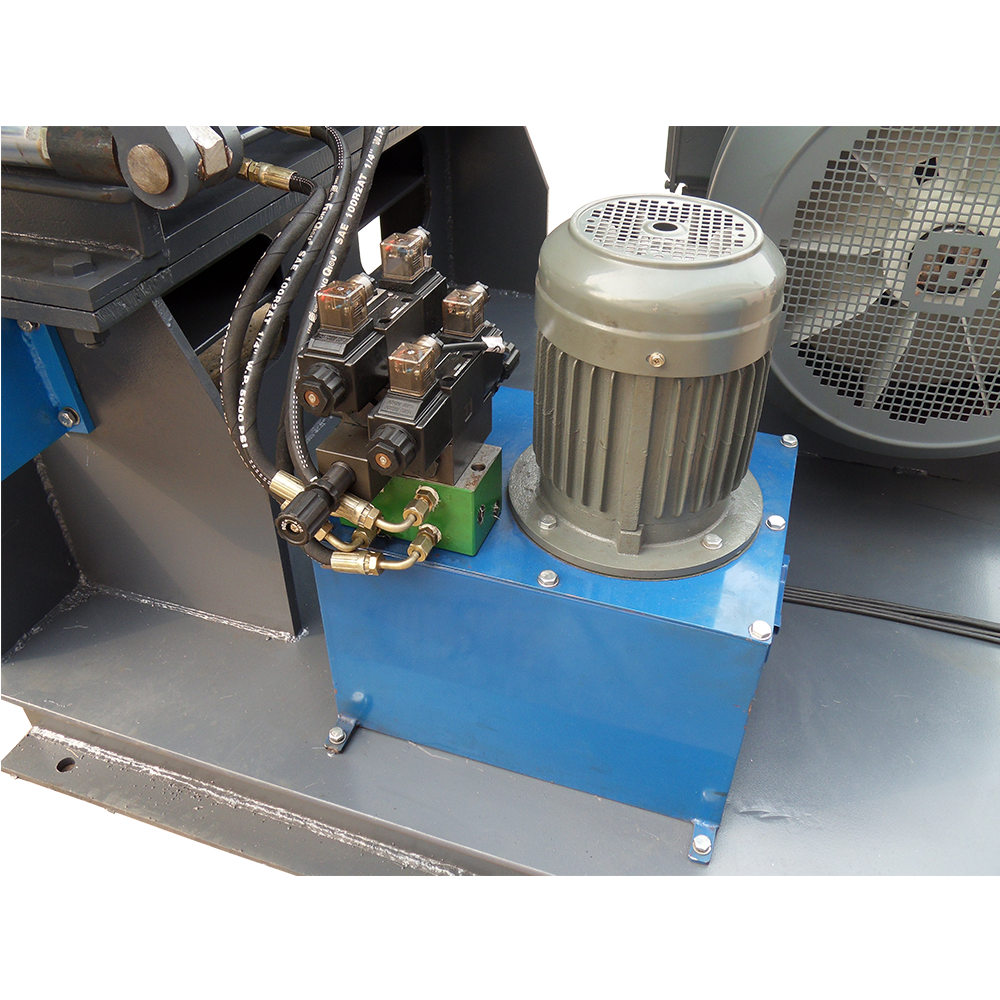

1. The cover is divided into upper and lower parts by the center line, and the upper part can be easily opened by hydraulic device. The screen is fixed by the front door screw right and separated from the upper part of the machine, and its disassembly and position lifting are carried out by hydraulic devices

2. The firm bearing device is installed on the outside of the machine, specially designed to meet demanding requirements and materials that are not easily broken and recycled. It is independent of the cutting chamber to prevent dust and dust from entering the bearing. at this point

Extends the life of the machine and reduces maintenance work. The advantage of an independent bearing separated from the crushing chamber is particularly significant for crushing with water.

3. MSH series rotor cutter adopts the latest V-shaped cutting technology. In the past conventional cutting technology, when the material is transported to the crushing cavity, the material will rush to one side. V-shaped cutting

The technology can send the material to be crushed to the center of the rotary knife during the recycling process, which prevents the material from sticking to the side wall and also increases the magic resistance of the side wall.

4. The rotary knife is not directly fixed with bolts in the traditional method, but is fixed on the tool holder by the thread of the knife plate after the rotary knife. This prevents the bolt from moving or falling off the tool holder.

5. The firm welded rigid structure has wide versatility. At the same time, the design of the removable deflection wedge (the third fixed knife), the rotor bearing seat, the tool holder and the rotating shaft added to this series of models can meet the most demanding requirements of crushed materials.

6. The deflection wedge, the detachable accessory with the third static knife, can be used to change the first cutting point of the crusher. This simple optional device makes the machine more versatile. When crushing difficult materials, the possibility of the rotary knife being blocked is eliminated.

7. The machine is equipped with safety protection devices to ensure the safety of operators.

Model | Motor power(KW) | Caliber (mm) | Fixed knife (PCS) | Reversing knife (PCS) | Ability to work(kg/h) | Gross weight(kg) | Mechanical Dimensions(mm) |

MSH-500/600 | 45 | 636*591 | 2/3 | 6/10 | 600-1100 | 3000 | 1620*1800*2830 |

MSH-500/800 | 55 | 800*591 | 4/6 | 6/10 | 700-1200 | 3500 | 1820*1800*2830 |

MSH-500/1000 | 75 | 1000*591 | 4/6 | 6/10 | 800-1350 | 4000 | 2020*1850*2830 |

MSH-500/1200 | 90 | 1200*591 | 4/6 | 6/10 | 800-1500 | 4500 | 2220*1850*2830 |

MSH-600/800 | 75 | 800*690 | 4/6 | 6/10 | 700-1300 | 5000 | 1810*2200*3500 |

MSH-600/1000 | 90 | 1000*690 | 4/6 | 6/10 | 800-1500 | 5500 | 2000*2200*3500 |

MSH-600/1200 | 110 | 1200*690 | 4/6 | 6/10 | 900-1650 | 6000 | 2320*2220*3500 |

MSH-600/1600 | 132 | 1600*690 | 4/6 | 6/10 | 1000-1800 | 7000 | 2750*2400*3850 |

MSH-700/1000 | 90 | 1000*800 | 4/6 | 10/14 | 900-1650 | 7500 | 2000*2350*3850 |

MSH-700/1200 | 110 | 1200*800 | 4/6 | 10/14 | 1000-1800 | 8000 | 2300*2350*3850 |

MSH-700/1600 | 160 | 1600*800 | 4/6 | 10/14 | 1100-2000 | 9000 | 2700*2550*4200 |

MSH-800/1200 | 132 | 1200*910 | 4/6 | 10/14 | 1300-2200 | 11000 | 2350*2720*4600 |

MSH-800/1600 | 160 | 1600*910 | 4/6 | 10/14 | 1400-2400 | 12500 | 2700*2720*4600 |

MSH-800/2000 | 200 | 2000*91 | 4/6 | 10/14 | 1600-2600 | 13500 | 3200*2880*4600 |