- Details

Features:

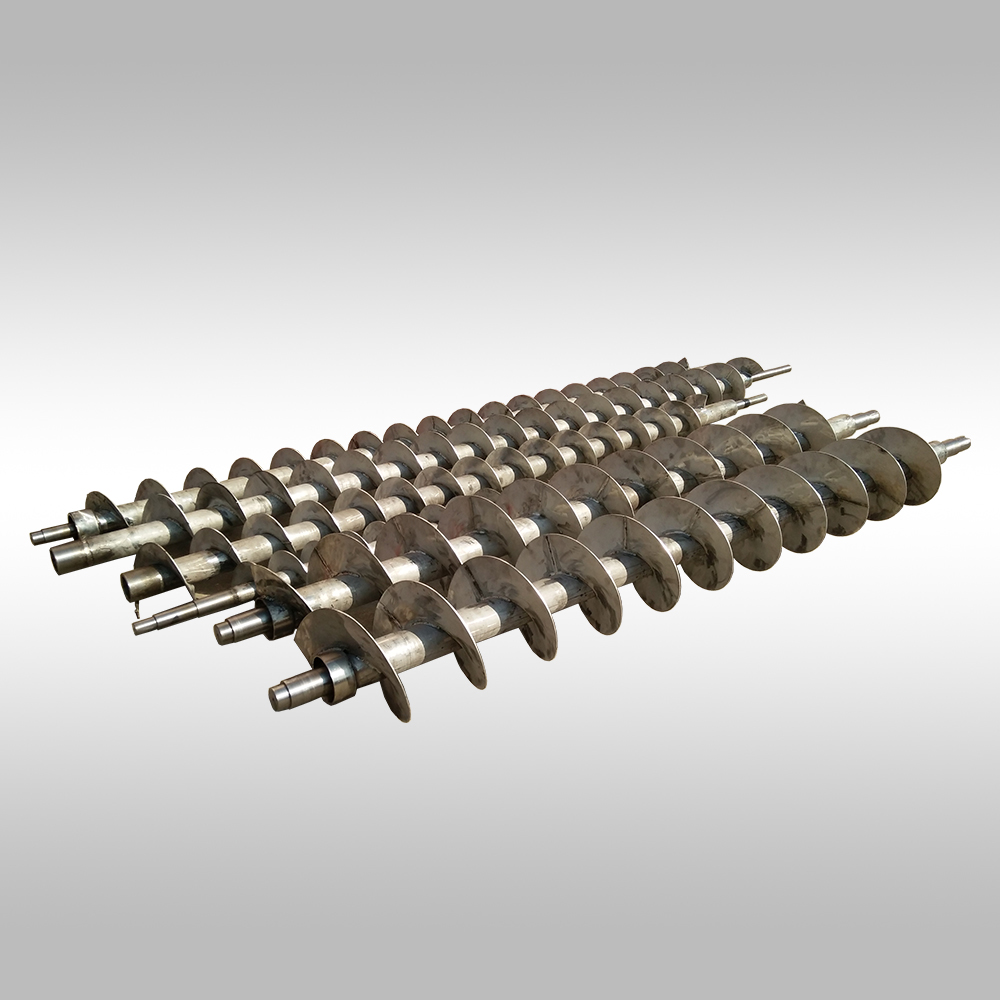

1. The part in contact with the material is made of stainless steel, which is easy to clean and avoid corrosion.

2. Spiral circulation stirring makes the mixing of raw materials more uniform and fast.

3. It is suitable for mixing and mixing various plastic raw materials and color masterbatches, and the mixing effect of new and old materials and color masterbatches is better.

4. The working method of mixing while feeding materials can greatly save time.

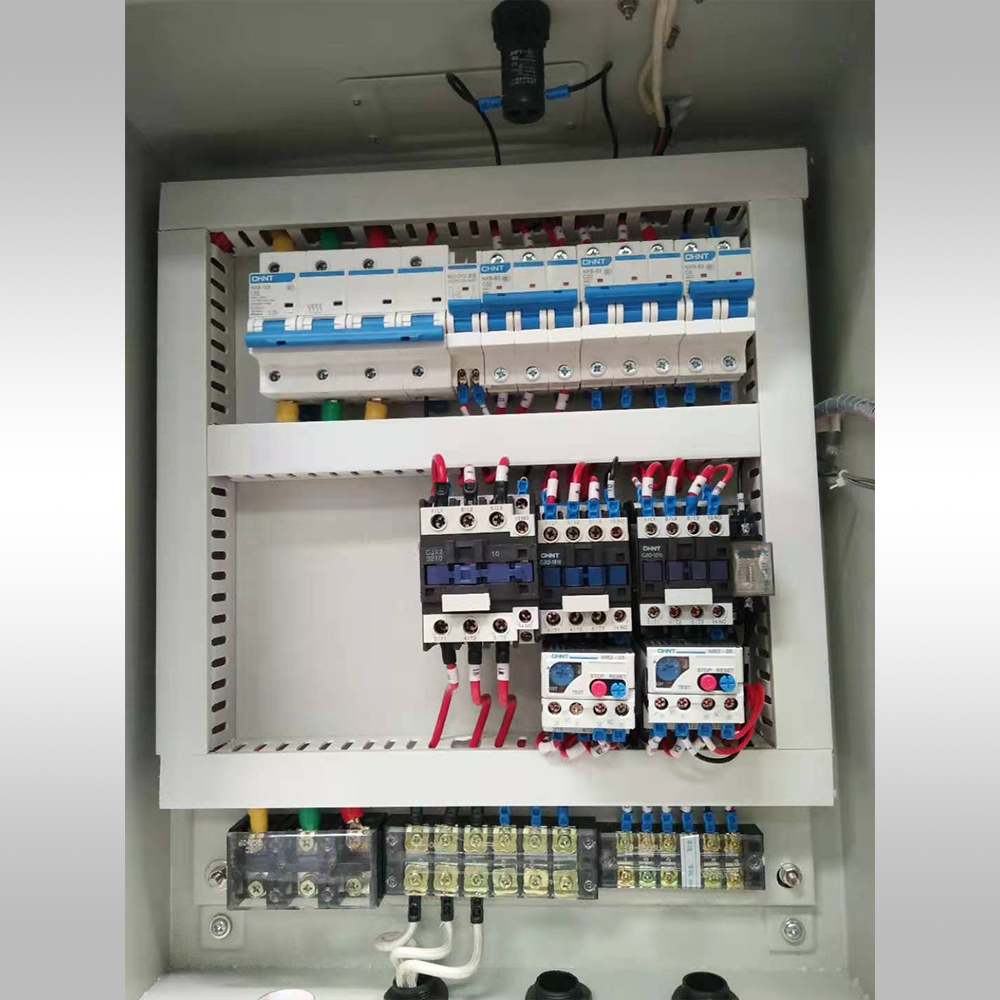

5. Equipped with electric control safety protection device to ensure safe operation.

6. With automatic stop device, it can be set to stop automatically in 0-30 minutes.

7. Drying type can be customized.

MS series spiral mixer is mainly used for mixing and mixing of plastics, such as mixing and mixing of raw materials and color masterbatch, and mixing and mixing new and old materials and color masterbatch.

Working Principle:

The working principle of the MS series screw mixer is to use the rapid rotation of the motor drive screw shaft to lift the raw materials from the bottom of the barrel from the center to the top, and then throw them in an umbrella shape. The raw materials are constantly tumbling in the barrel, and a large amount of raw materials can be completely uniformly mixed in a short time, and then discharged from the large discharge port

Standard:

Model | Power (KW) | Capacity(L) | Rotating Speed(r/min) | Dimensions(mm) | Weight(kg) |

MS 500 | 3 | 1000 | 330 | 1200*1250*2500 | 400 |

MS 1000 | 4 | 2000 | 330 | 1500*1580*2750 | 550 |

MS 2000 | 5.5 | 4000 | 330 | 1800*1880*3300 | 800 |

MS 3000 | 7.5 | 6000 | 330 | 2000*2080*3700 | 1000 |

MS-5000 | 11 | 10000 | 330 | 2400*2480*4200 | 1200 |

Remarks: can be customized with drying type

The standard model voltage is three-phase 380V 50HZ.